Cold Change blast chiller tunnels are designed to freeze all types of products including

- Pre-cooked bread

- Bread dough

- Cakes

- Sea food and meats

- Vegetables

- Other – Also used for industrial processes such as wax solidification, the cooling of metal parts or any other continuous cooling process.

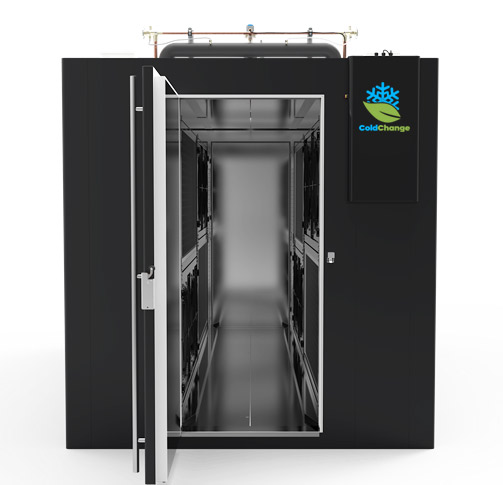

Cold Change model: CC-TC-460

Capacity: up to 10 trolleys

- 6 cars / trolleys (800 x 850 x 190)

- or

- 10 cars / trolleys (670 x 450 x 190)

Not what you are looking for? click here

Number of fans: 12

Power (Kw) -32 C – +40 C: 62.2 KW

Refrigerant: R449a

Cooling times: 6 – 21 minutes

Customised solutions: (please contact us for more information by filling our an enquiry form)

On request, the tunnels can be manufactured with different dimensions to adapt to the dimensions of special trolleys or conveyor sections.

Innovation

Cold Change blast chiller tunnels are the best quality blast freezer available on the market today. Our products are all designed with customer needs in mind. We have created an operating platform that is safe, simple and easy to use for operators. Each Cold Change product has been carefully optimised and programmed to cool your product in the most energy efficient sustainable way possible.

Food hygiene safety and EU guidelines and legislations have all been met

Cold Change products are made using high quality materials which is easy to see and clearly noticeable during operation.

Our machines have a smart control system managed by a PLC control system with a touch screen interface that displays the status of your cooling cycle including how many carts you have inside using a clever sensor system. The operator can create consistent results even with variable products to cool by setting up multiple product based perimeters which can be saved and easily selected per product.

Technical data:

Energy efficient thanks to thermal insulation by means of a 100 mm thick refrigerator panel with hermetic doors with oleodynamic closing and variable speed electronic fans.

Automated control of the equipment by means of PLC with touch screen user interface, which allows modifying the operating parameters in real time and displaying data such as temperature, ventilation speed, the number of trolleys inside, the residence time of each one, the opening of the doors, the end of cycle warning, etc.

Refrigeration components: Evaporators with aluminum fin and copper circuit.

1 or 2 Cold Change Thermo machines remote condensing units equipped with a semi-hermetic compressor and a high efficiency aluminium micro channel condenser.

Contact on Linked In

المراجعات

لا توجد مراجعات بعد.